1. Model: BPFBM-24A2 /32A2/48A2

2. Performance features

· On-line Performance: very good (Designed as per the on line equipment of the production line)

· Beveling Speed: ≤3Min /pipe bevel (DN200 SCH40) /≤5Min /two pipe bevels (DN200 SCH40)

· Bevel cutting: cutting off & with one bevel of the pipe at simultaneously for /cutting off & with two bevels of the pipe at simultaneously

· Bevel quality: good

3. Technical parameters

· Pipe diameter applicable: DN100~600(φ114~610)

· Applicable wall thickness: 5~50 mm

· Materials applicable: carbon steel, alloy steel, and cryogenic steel

· Cutting length: 6350MM

· Bevel Shape: V

· Cutting direction: lengthwise

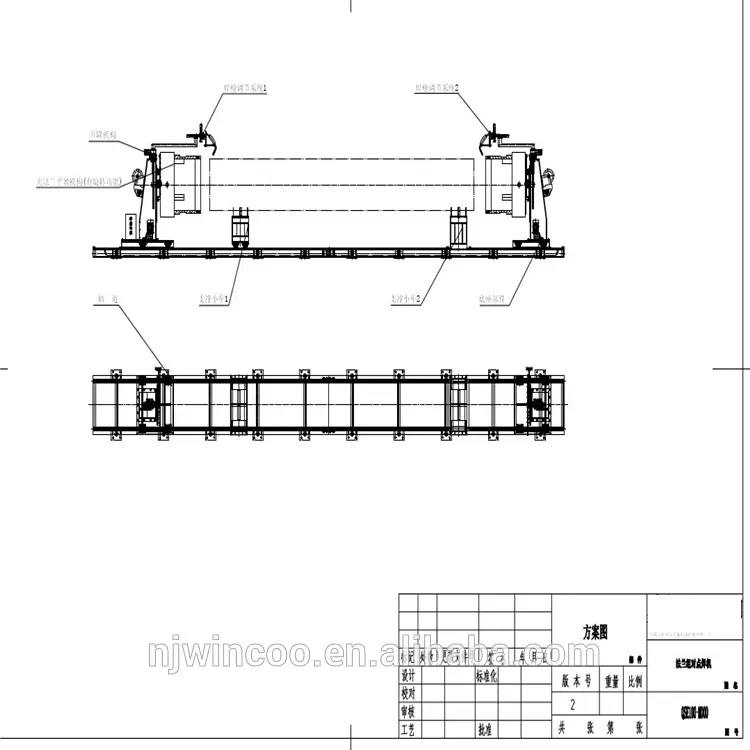

· Roller bench:

Structure: Three line steel roller with fixed distance

Roller Bench Length:7000MM

Driving System: servo motor + precision reducer

Rev: 0~2.5M/Min (VF stepless speed adjustment)

Roller bench Material:45#, Surface bluing treatment

Rotation Accuracy:<2.0MM

· Trolley System:

Trolley travel: 6350MM(moving lengthwise)

Cutting torch travel: 700MM (up/down); 300MM (in/out)

Cutting with: flame cutting(can be equiped with plasma cutting)

Cutting Torch Angle:±45°(adjustable)

Cutting Torch Quantity: one piece of flame cutting torch /three pieces of flame cutting torch

Angle error: <2°

Length fixing accuracy:<2.0MM

· Control System: SH-2000H Flame CNC Cutting System

· Length-measuring system: CNC length measuring which is included in the control system.

Conveying system: built in a conveying system equipped with a lifter; one set of conveying system can be provided additionally for bevel cutting machine if necessary and conveying can be implemented manually or electrically.

Related products