1.Application

2M58ZSM7.5×6 is used for internal/external circumferential and longitudinal seam, cladding seam grinding and gouge of boiler, pressure vessel and related vessels.

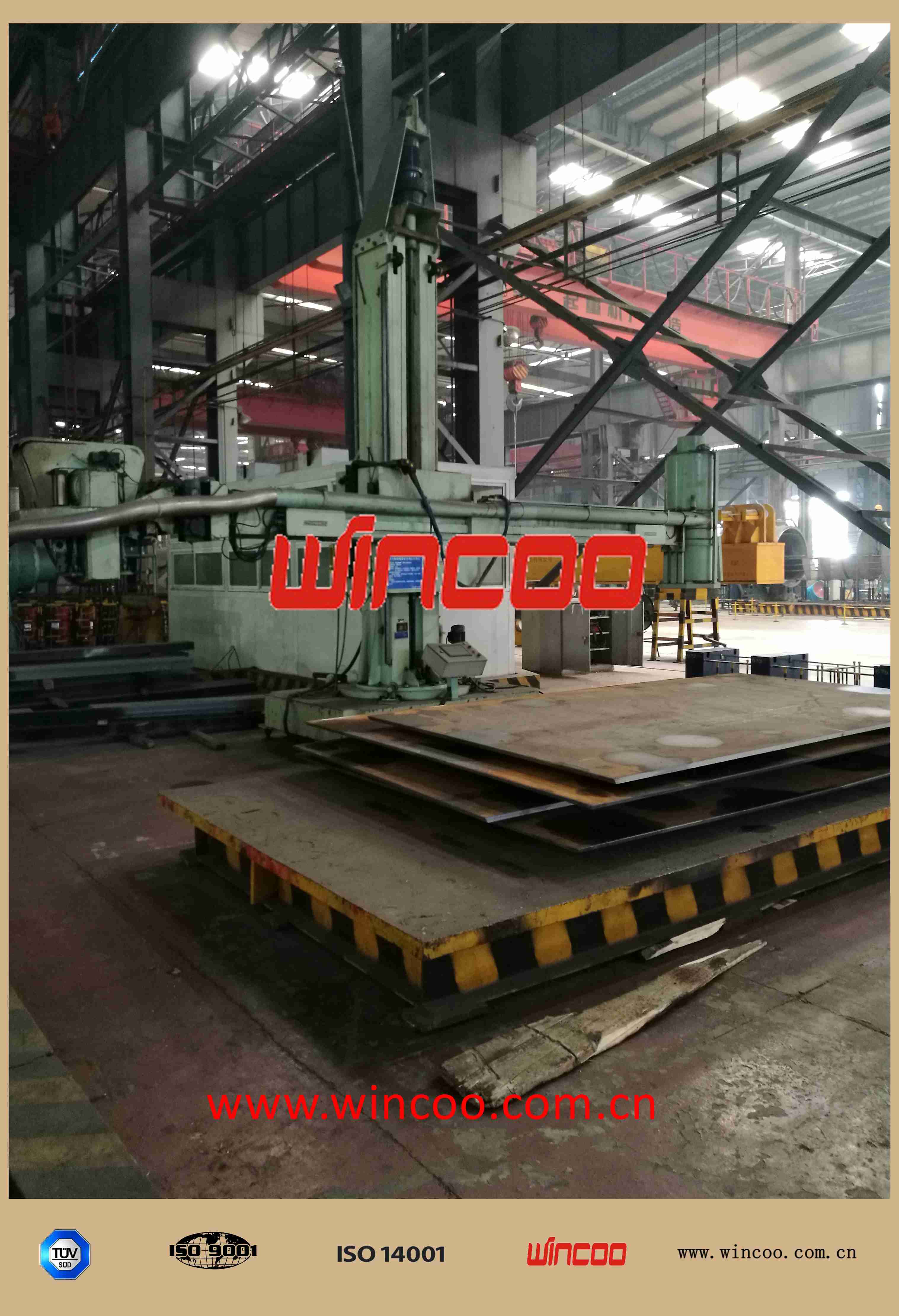

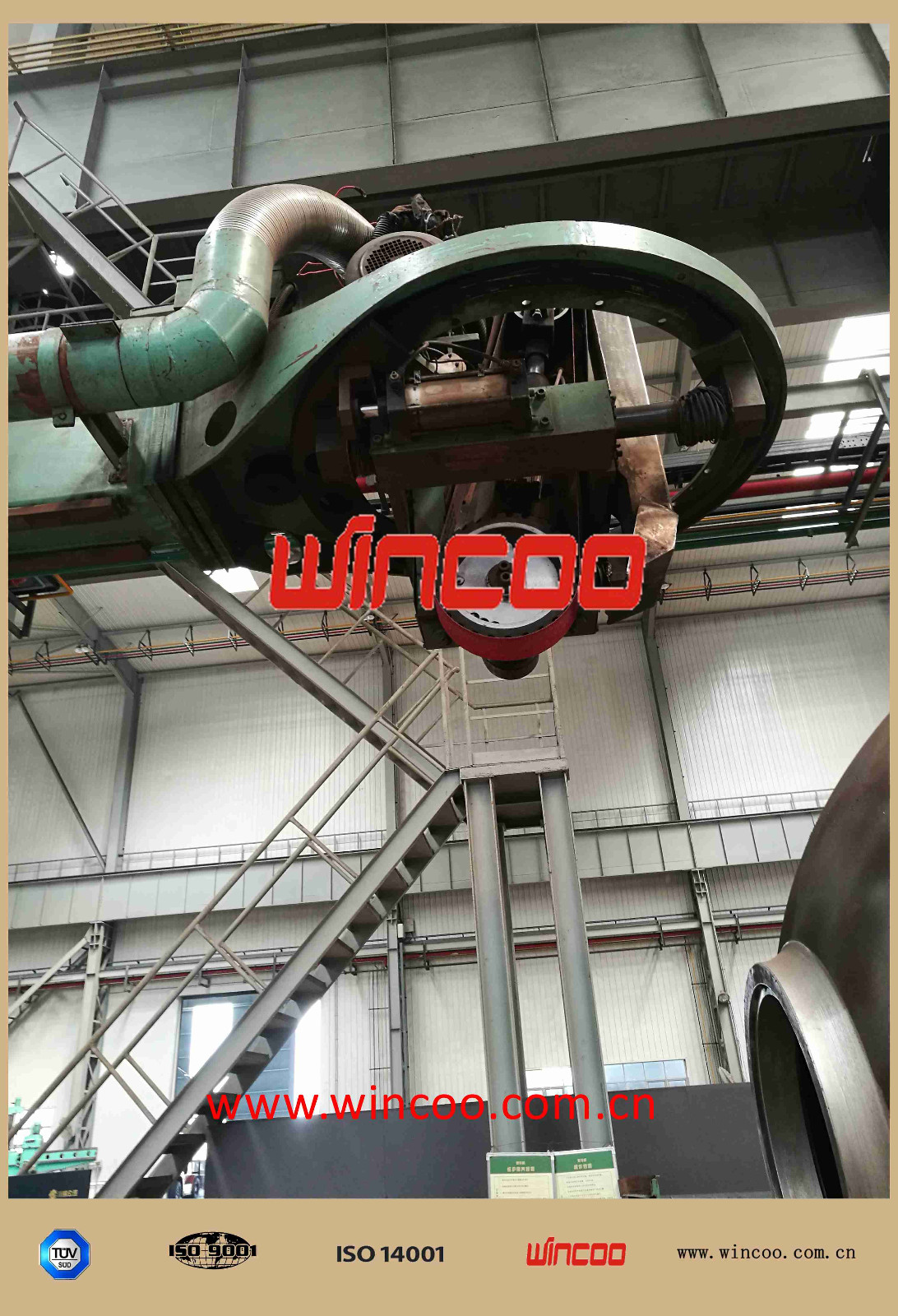

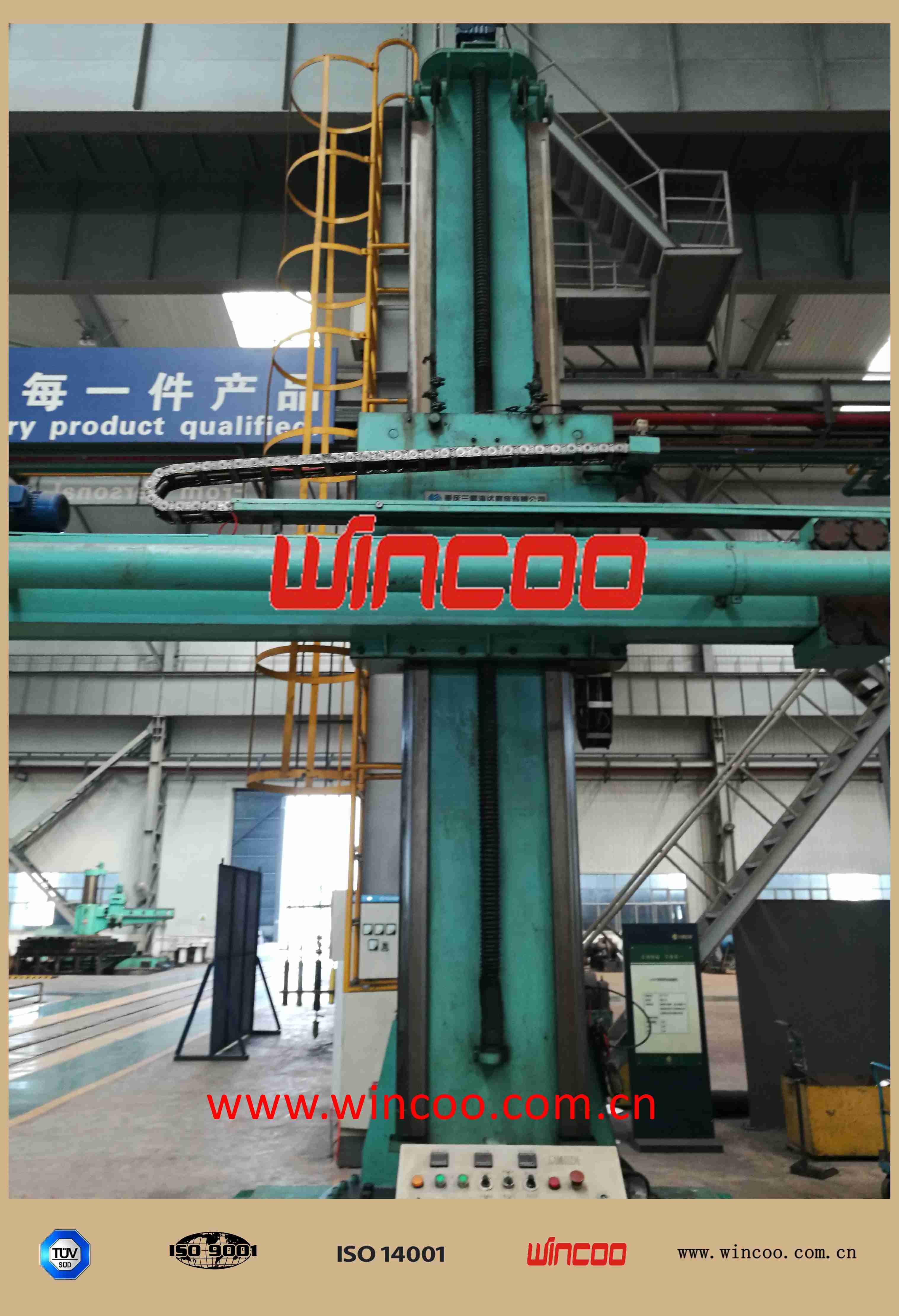

2.System configurations and technical data (Please refer to following chart and pictures )

2.1. System configurations

It consists of ZSM7.5×6 cross manipulator, MW-1300 multifunctional abrasive wheel and abrasive belt head, SG*5.0 dust removal system, pneumatic control system and related electronical system.

2.2. Main technical data.

Suitable workpiece size | ||

SN | ITEM | DATA |

1 | Maximum each pressure section / plate length | ≤4000mm |

2 | OD of pressure vessel | 800~6000mm |

3 | Minimum gouge Internal diameter (with dust removal system) | 1800mm(Grinding internal longitudinal seam welding seam 2400mm) |

4 | Minimum grinding Internal diameter (with dust removal system) | 1800mm(grind internal longitudinal seam2400mm) |

5 | Workpiece material suitable | Low alloy steel, High Alloy steel, Stainless steel and Carbon steel |

Manipulator | ||

1 | Minimum Height from Grinding & gouge head to ground | 900mm |

2 | Lateral beam lifting height | 7500 mm |

3 | Vertical moving maximum speed (frequency control) | 100~1000mm /min |

4 | Lateral beam stroke | 6000 mm |

5 | Lateral moving maximum speed (frequency control) | 100~1000mm /min |

6 | Column Rotation available degree | ±180° |

7 | Column Rotation speed | 12°/min |

8 | Lateral beam deflection | 2.0mm/m |

Multifunctional abrasive wheel and abrasive belt head | ||

1 | Grinding & gouge head rotation degree | 0~90° |

2 | Grinding & gouge head elevation angle | 0~90° |

3 | Grinding & gouge head vertical rotation angle | ±90° |

4 | Grinding & gouge head right/left moving distance | ±75mm |

5 | Side swing and relocation distance | ±50mm |

6 | Grinding & gouge head relcation blade lifting stroke | 180mm |

7 | Size of abrasive belt connect wheel | 300×100mm |

8 | Belt size | 2800×100mm(perimeter* width) |

9 | Abrasive belt grind speed(Stainless steel cladding and welding seam weld reinforcement ) | 30m/s(frequency control) |

10 | Abrasive wheel size | 650×B×80mm(B=16,18,20,22) |

11 | Abrasive wheel maximum gouge speed | 65m/s(frequency control) |

12 | Pressure adjustment ranges | 0~2000N(Proportional valve is adjustable) |

13 | Gouge power | 18.5kW |

Grinding and gouging performance data | ||

1 | Weld Root gouging maximum depth | 170mm |

2 | Gouge Width of abrasive wheel | 16~22mm |

3 | Maximum depth for each time grinding & gouge | 5mm |

4 | Gouge speed | 100~1000mm /min |

5 | Root pass gouge and grinding maximum size | 100×5mm |

6 | Longitudinal seam gouge right/let straightness | ≤5mm |

7 | Single Time maximum grinding margin | 100×5mm |

8 | Abrasive grinding speed | 100~1000mm /min |

9 | Cladding welding maximum grinding margin (Abrasive belt) | ≥0.5mm/time |

10 | Cladding welding layer maximum grinding power | 18.5kW |

11 | Seam grinding Surface Roughness | ≤Ra12.5μm |

12 | Cladding welding grinding surface roughness | ≤Ra6.3 |

13 | Bevel grinding | ≤Ra12.5μm |

Dust removal system data | ||

1 | Power | 5.5 kW |

2 | flow rate | 3700m3/min |

3 | (Ptf)Full pressure | ≥2216pa |

4 | dust remove efficiency | 70% |

5 | Total weight | 35T |

6 | otal Power | 35 kW |

7 | Machine size | 8000×10000mm(Dimeter×height) |

Related products